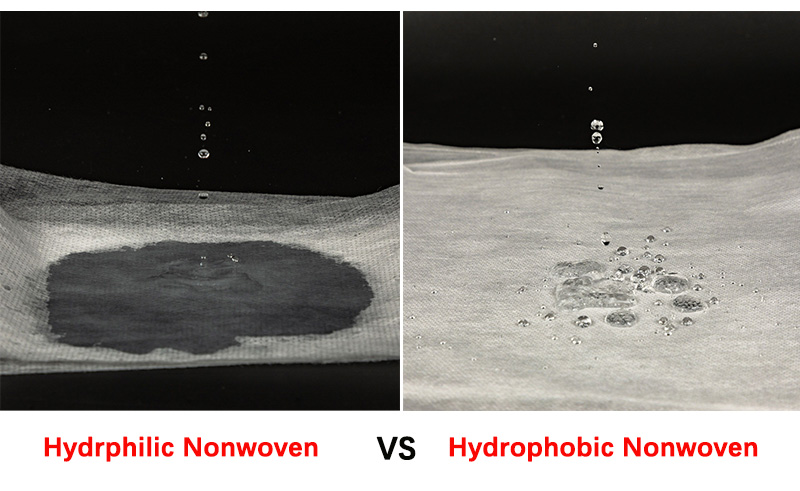

In the production of hygiene products, nonwoven fabric is a key raw material that determines the product’s comfort, absorbency, and overall performance. Based on surface properties, nonwoven fabrics can be classified as hydrophilic or hydrophobic, and each plays a distinct role in items such as baby diapers, adult incontinence products, and sanitary napkins.

Hydrophilic Nonwoven Fabric – Fast Absorption and Soft Touch

Hydrophilic nonwoven fabric allows liquid to spread and penetrate quickly into the absorbent core, keeping the surface dry and comfortable.

It is commonly produced using spunbond or hot-air technologies:

1. Spunbond hydrophilic nonwoven is treated with hydrophilic finishing agents or blended with hydrophilic masterbatch to achieve quick liquid transfer with uniform structure and high efficiency.

2. Hot-air hydrophilic nonwoven uses bi-component fibers (PE/PP), giving it a softer and bulkier texture, often used in premium diaper topsheets.

Key Features:

* Rapid liquid transfer and low rewet;

* Soft, skin-friendly surface;

* Even distribution of liquid for a dry and comfortable feeling.

Hydrophobic Nonwoven Fabric – Leakage Protection and Durability

Hydrophobic nonwoven fabric repels liquids, serving as the protective layer of hygiene products.

It is usually made using spunbond or SMS/SMMS composite technologies:

1. Spunbond hydrophobic nonwoven uses the natural water-repellent properties of PP fibers or applies a hydrophobic surface coating.

2. SMS nonwoven combines meltblown and spunbond layers to improve barrier and breathability.

Key Features:

* Prevents leakage and liquid penetration;

* Keeps the outer layer dry and clean;

* Provides good strength and stability to the product.

Applications

Conclusion

Hydrophilic and hydrophobic nonwoven fabrics complement each other in hygiene products — one ensures quick absorption and comfort, while the other guarantees protection and dryness. Choosing the right production technology (hot-air, spunbond, or SMS composite) and surface treatment is essential for creating high-quality hygiene materials.