Material: Nonwoven

Type: Disposable

MOQ: 500KG

Payment Iterm: L/C; T/T

Delivery Time: within 20days

Free Sample Anion Chip Raw Material for Sanitary Napkin/Sanitary Pad

Product Details:

| Product Name: | Anion Chip for Sanitary Napkin Raw Materials |

| Color: |

Can be Customized |

| Weight: | 60-130GSM |

| MOQ: | 500kgs |

| Delivery Time: | Within 20days |

1) PE film and cloth-like film materials

2) PP/MAGIC Side/Frontal Tape

3) Hot-melt glue(Spandex/Structure)

4) Fluff Pulp(treated/untreated)

5) SAP

6) Jumbo tissue paper(Upper/Lower Tissue Paper)

7) Non-Woven (Topsheet-Hydrophilic N.W./ leakage-Hydrophobic N.W.)

8) Spandex / Waistband.

9) Release tape for sanitary napkin

10) Released paper (winged/back of sanitary pad)

11) Sap absorbent paper

12) Airlaid Paper

Packing & Shipping

Wrapped film with plastic cover,10rolls/pack

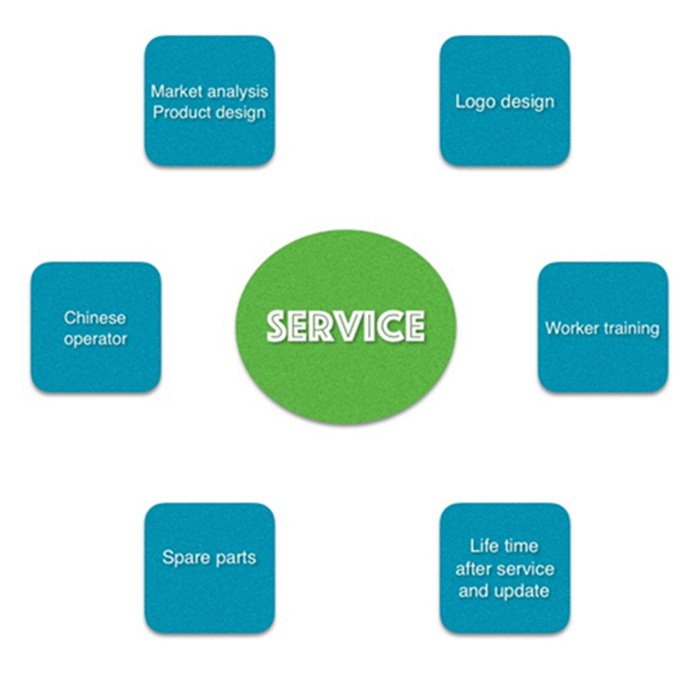

Quanzhou Niso Industry Co.,Ltd is your best choice for diaper raw material, sanitary napkin material and disposable hygiene products in China.