item no.:

NSKZ/100Payment:

80%TT as deposit,20%TTbalance before shipmentmarket price:

$44300product origin:

ChinaColor:

According to customer's needsshipping port:

Xiamen port,ChinaLead Time:

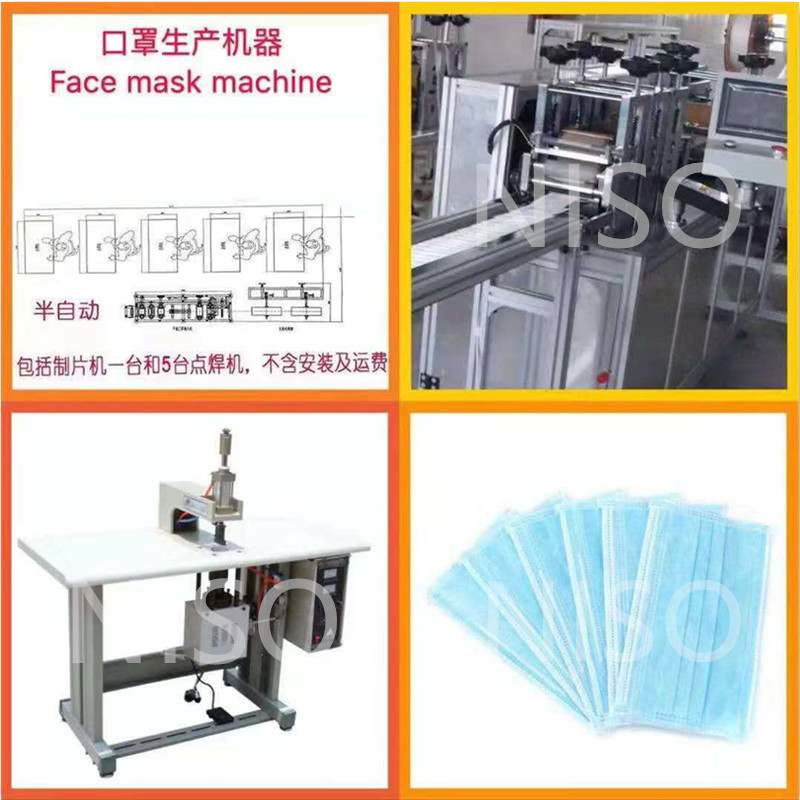

20-30 working days after get 80%depositSemi-automatic face mask making machine

1. Application of the machine:

Used in the production of disposable masks.

2.Technical specification:

★Specification:175mm*95mm;

★ Structure:Ear loop+Toplayer N.W+Noswire+Filter N.W+Butoom layer N.W

★ Designed Speed:100pcs/Min;

★ Power:380V 50HZ;

★ Capacity:7KW;

★ Air pressure:0.6~0.8Mpa,1.0 cbm/min;

★ Wastage:≤1%(not including the defective products caused by glue machine andjoint materials);

★ Efficiency range:≥85%;

★ Machine size: L*W*H≈2.2M*2.1M*1.5M;

★ Weight:1.2T

For more details of the machine, please contact us for communication.

www.qzniso.com

Quanzhou Niso Industry Co.,Ltd is your best choice for diaper raw material, sanitary napkin material and disposable hygiene products in China.