semi-Servo Underpad Production Machine (CD150-HSV)

high speed underpad production machine

specialized underpad manufacturing machine

high efficient underpad making machine

China economic underpad making machine

supply underpad machinery

specilalized underpad production line

item no.:

CD200-SVPayment:

TT/LCmarket price:

$10000product origin:

China, Fujianshipping port:

XiamenLead Time:

120 days after deliveryHigh Quality Servo Control Underpad Machine (CD150-HSV)

Main Technical Parameter for Underpad Machinery

|

Machine model |

CD 150-HSV Underpad Making Machine |

|

Design Speed |

150 meters/min |

|

Stable Production Speed |

100 meters/min |

|

Start production Speed |

250 KW |

|

Practical capacity |

150 KW |

|

Breaker |

600 A |

|

Supply Power |

380V AC, 50HZ, 3 phase 5 wire ( According to customer) |

|

Machine Weight |

30 Ton |

|

Machine Size |

22m*8m*3.5m ( L*W*H) |

|

Reject rate |

≤ 2% |

|

Efficient rate |

≥ 85% |

|

Air |

0.6-0.8 M Pa |

|

Noise |

<87db (A) |

|

Finished Products |

good quality and normal quality under pad |

|

Packing |

Antirust Oil& PE Film

Cover & Seaworthy Wooden Box , 2*40HQ |

|

Certification |

CE, ISO, SGS |

Main Function Features of Underpad Production Line

1. Produce different sizes

of under pad

2. The quantity of SAP and fluff pulp

can be adjusted freely

3 Raw

materials automatic unwinding system, automatic splicing units, automatic

rejection units, automatic web guard system.

4. Under pad

machine is attached with fully automatic packing machine (stacker), make

packing simpler and save labor force

5. Under pad

machine equipped with production door

6. Touchable Screen: Machine

switch on/off, running speed, time, counting pieces, parameter setting, alarm, error

display, error enquiry(functions setting appear on screen are different

according to different machine type)

Machine Processing

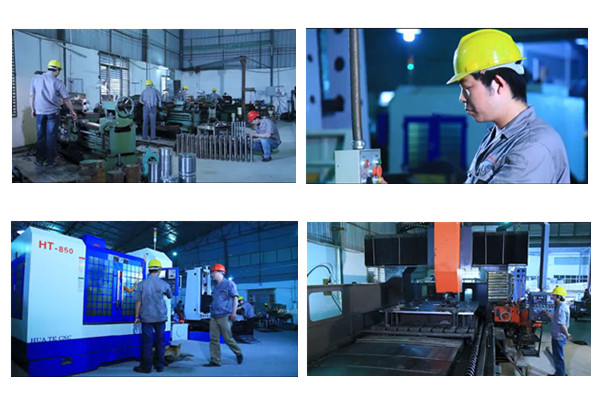

Our Workshop

Packing & Delivery:

Packing: Standard export package: pant anti-rust oil on machine, wrap machine with plastic film,

then put machine in wooden cases.

Delivery Time: 120 days

Our Services

Why choose us?

√ Chinese Listed company since Nov.30th, 2012

√ ISO certificate, certificate of utility model patent, patent for invention for machine etc

√ Full support for your complete project

√ Customers from over 100 countries in the world till now

√ Very good machines and service at good price

√ Own parts processing workshop

√ Factory manufacturer, not trading company

Excellent After-sales service

1. Machine operation training

2. Machine operators available

3. Life-long after-sales service for machines.

Raw Materials Available for Diaper Manufacturing

Underpads: pulp + hydrophilic N.W + tissue paper + SAP + hot melt adhesive + elastic adhesive

Quanzhou Niso Industry Co.,Ltd is your best choice for diaper raw material, sanitary napkin material and disposable hygiene products in China.