100% PP Spunbond Hydrophobic Nonwoven fabric is used for the leg cuff of sanitary napkin,baby diabper,adult diaper, adult incontience diaper.

item no.:

Raw MaterialPayment:

TT,L/Cproduct origin:

ChinaColor:

multiple colorshipping port:

XiamenLead Time:

15days

100%PP Spunbond Hydrophobic Nonwoven fabric

★Specification

Material:100% Polypropylene

Nonwoven Technics: Spun-bonded

Weight:Regulaer 15-18gsm or according to your requirement

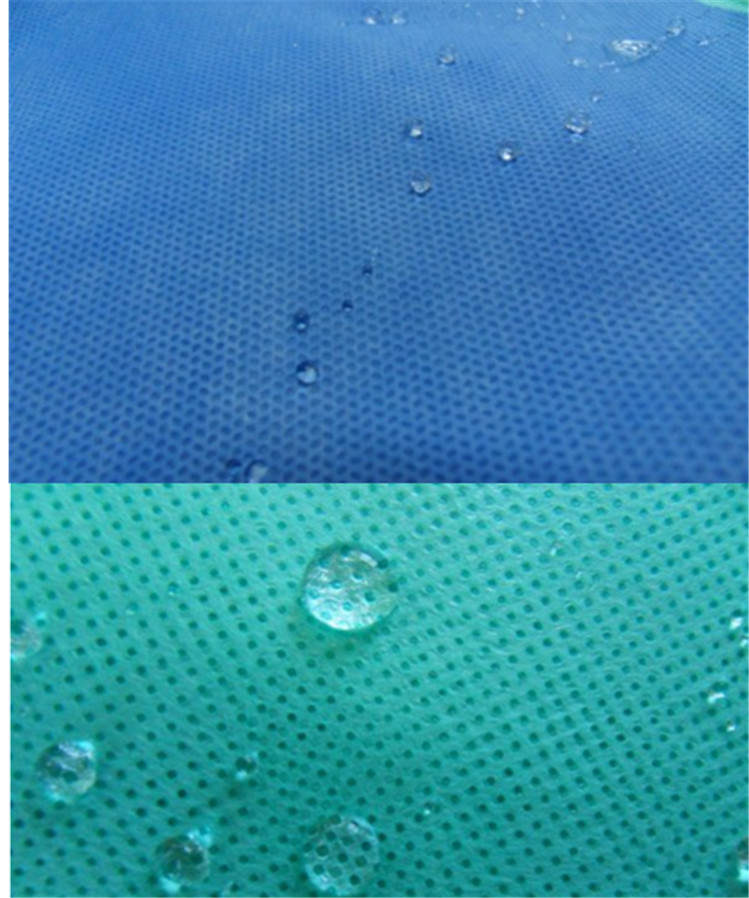

★Feature:

※ Good stability and

uniformity

※ Waterproof,Mothproof,Eco-Friendly

※ Breathable,Anti-Bacteria,Anti-Pull,

※ Tear-Resistant,Fusible,Shrink-Resistant

※ Non-toxic,non-irritating

★Applience

|

1.Disposable

personal healthcare products |

|

2.Women’s

sanitary napkins, sanitary pads, baby diaper, adult diaper,adult

incontinence. |

|

3.Disposable

medical protection products |

|

4.Surgical

coat, cap, shoe cover |

|

5.Industry

protection products |

|

Roll

with paper tube in the polybag,or according your requirement. |

★Technique

date

Tensile strength (MD) 12-35N/5 cm Tensile strength (CD) 3.5-12N/5 cm Elongation (MD) 15-70% Elongation (CD) 30-90% Normal strike-through time <3 sec. Usage The leg cuff of Sanitary Napkin/Baby Diaper/ Adult Diaper

The details picture of 100%PP Spunbond Hydrophobic Nonwoven fabric

Contacts: wendy

E-mail: wendy@qzniso.com

Tel: 0086-595-87619521

Mob: 0086-150 6088 1636

Skype: wendy_niso

Why Choose us?

1. CE,ISO,SGS certificate for hygiene raw materials, non woven, back sheet, hook &loop, spandex, waist band. Global famous brand for pulp, SAP, glue.

2. International standard lab testing for raw materials & ready products.

3. Professional service team: 5 overseas sellers with more than 5 years experience, 3 lab technicien with more than 10 years experience, 3 QC with more than 5 years experience.

4. Export more than 1000 containers raw materials per year to Asia, Africa, Mid-east, America, Europe countries.

5. All-round service for whole industry including raw materials offer & testing, ready product offer & testing, machine offer & suggestion, chinese technicien offer and so on.

About us:

Quanzhou Niso Industry Co.,Ltd is your best choice for diaper raw material, sanitary napkin material and disposable hygiene products in China.